Challenges with Shipping Container Visibility

The usual practice of tracking shipping containers involves built-in or user-installed GPS, a method that introduces various challenges.

CHALLENGE #1

This data provides just the container's location and is not actionable enough to optimize its use at scale.

CHALLENGE #2

It isn't easy to aggregate container data from multiple vendors onto a single platform and ensure accuracy.

CHALLENGE #3

It is not easy to monitor the condition of the goods inside the container.

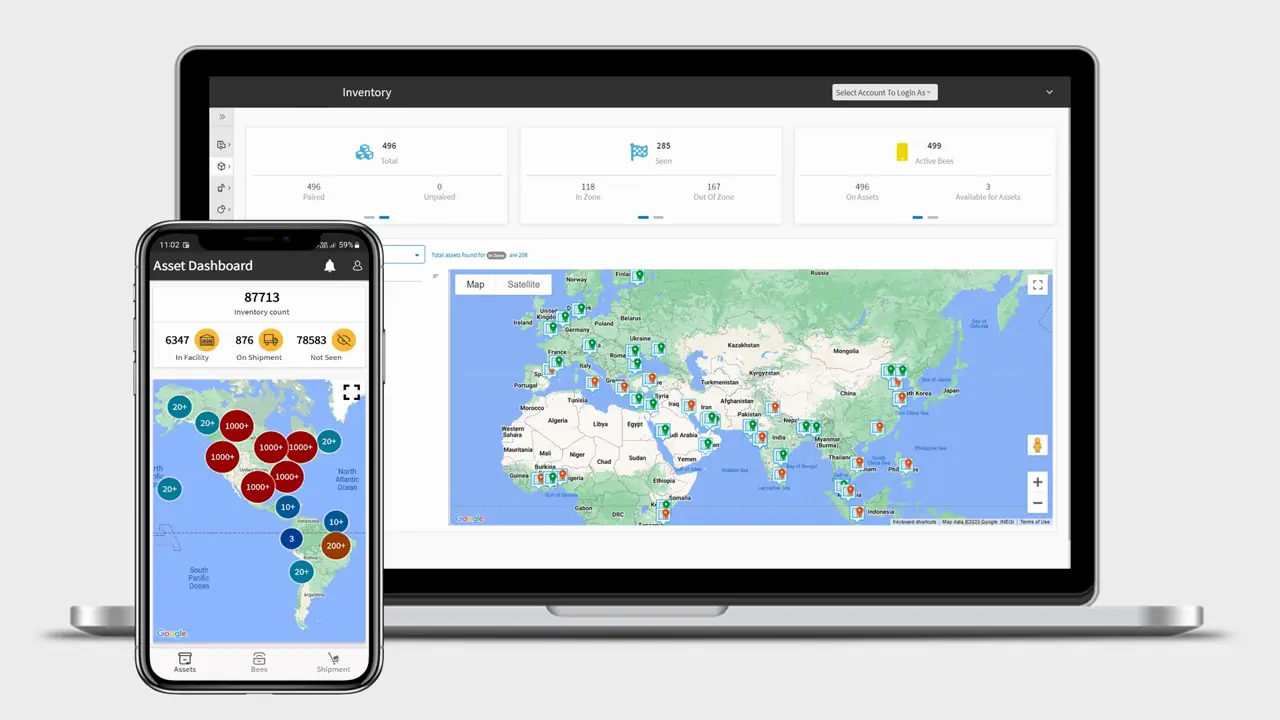

How Roambee's Solution Works for Shipping Containers

Visibility

Better visibility by combining order information with real-time location and condition data from IoT sensors affixed on shipping containers capable of recharging using renewable solar power and data streams from marine traffic, vessels, and port operations.

Alerts & Signals

Built on verifiable visibility, alerts & signals empower better decisions and drive automation. For example, a business signal about container availability is derived by sensing use cycle milestones and full/empty status to maximize usage and rentals.

Intelligence

Use AI-powered network insights & foresights for better supply chain planning & execution. For example, score unproductive container dwell times by geography, season, customer, and carrier and forecast this key performance indicator (KPI).

Experience the Power of Roambee

Experience the Power of Roambee

Alerts & Signals to Help You Make the Right Decisions

Enhance your strategic decision-making with real-time alerts and actionable insights, ensuring prompt and appropriate responses to any disruptions or irregularities in your shipping container asset management.

Asset Signals

Route Deviation of

Shipping Containers

Electronic Proof of

Delivery (ePoD)

Temperature & Humidity

Excursion

Mean Kinetic

Temperature (MKT)

Time Out of

Refrigeration (TOR)

Tilt & Shock

ETA & Delay Signals

Pick-up & Delivery

Location & Geofencing

In Use (On a Shipment)

Idle at Ports, CFS,

Storage Terminations, etc.

Idle at a Customer

or Vendor Location

Authorized & Unauthorized

Container Door Opening

Route Deviation of

Shipping Containers

Electronic Proof of

Delivery (ePoD)

Temperature & Humidity

Excursion

Mean Kinetic

Temperature (MKT)

Time Out of

Refrigeration (TOR)

Tilt & Shock

ETA & Delay Signals

Pick-up & Delivery

Location & Geofencing

In Use (On a Shipment)

Idle at Ports, CFS,

Storage Terminations, etc.

Idle at a Customer

or Vendor Location

Authorized & Unauthorized

Container Door Opening

Business Signals

Delivery & Pickup Window Schedule

Container Handling (Product Damage)

Shipping Container Usage SLA Violations

Delivery & Pickup Window Schedule

Container Handling (Product Damage)

Shipping Container Usage SLA Violations

Full/Empty Status Signals of Shipping Containers

Wrong & Missed Connections of Shipping Containers

Shipping Container Availability for Product Shipping

Full/Empty Status Signals of Shipping Containers

Wrong & Missed Connections of Shipping Containers

Shipping Container Availability for Product Shipping

Aging of Containers at Ports, CFS, Storage Terminals, or Customer/Vendor Locations

Order Fulfillment in Container Operations & Product Shipping Operations

Revenue Recognition in Container Operations & Product Shipping Operations

Cold Chain Compliance Prediction of Goods inside Shipping Containers

Order Fulfillment in Container Operations & Product Shipping Operations

Revenue Recognition in Container Operations & Product Shipping Operations

Cold Chain Compliance Prediction of Goods inside Shipping Containers

Aging of Containers at Ports, CFS, Storage Terminals, or Customer/Vendor Locations

Business Outcomes with

Roambee

Business Outcomes with Roambee

Transform your container operations with Roambee. Achieve seamless global orchestration, maximize revenue per container, and enforce SLAs. Enhance sustainability with efficient routing and reduced operational distances.

- Seamlessly orchestrate the placement and retrieval of containers at every port and container freight station (CFS) around the world.

- Increase "revenue per container" with better utilization and lower idle times.

- Enforce service level agreements (SLAs), avoid "no-go" zones, and automate billing with data about acceptable use and violations by any actor in the chain of custody.

- Increase sustainability by routing containers across customers more effectively and reducing operational mileage.

Empowering you with our Intelligence

Unlock Roambee’s AI-powered insights for container management. Dive into asset cycle times, dwell and detention analytics, and ensure quality compliance. With Roambee’s foresights, anticipate SLA violations, optimize dwell times, and ensure consistent OTIF performance.

Insights

- Asset (container) cycle time analytics by geography, season, customer, vendor, etc.

- Dwell time and detention analytics by facility, port, CFS, storage terminals, and customer locations.

- Quality compliance (QC) performance across lanes, carriers, and nodes for cold chain and handling.

Foresights

- Asset dwell time and cycle time predictions by customer, geography, and season.

- Acceptable use service level agreement (SLA) violation predictions by lanes, regions, and customers.

- OTIF and quality control (QC) SLA predictions by lanes, carriers, etc.

Revolutionizing Container Fleet Management for a Leading OOG Cargo Operator in APAC

- About: A top Out-Of-Gauge (OOG) Cargo operator in the APAC region sought to enhance and automate its container fleet management.

- Roambee's Intervention: Utilizing Roambee's intelligence, the operator integrated real-time container location and status (full/empty) data with historical dwell times across all CFS, ports, and storage terminals.

- Results: This comprehensive approach led to a remarkable increase in "revenue per container" by over 77%, achieved through refined rental patterns, improved routing, and enforceable SLAs.

- Impact: The company realized optimized fleet operations, increased revenue, and ensured adherence to service level agreements.

Resources on Visibility & Intelligence

Webinar

How IFCO Has Found The Missing Piece Critical To Your Supply Chain

E-book

Making Smart Supply Chain Decision in the New Normal