Better Visibility & Intelligence for Railcars and Rail Boxes

Bring certainty into the complexity of rail transport to deliver high customer satisfaction with accurate rail ETA predictions and full/empty status data. Optimize your railcar fleet and ensure continuous availability of railcars or rail boxes when you need them for shipping – with intelligence at a railcar level and a rail network level.

Comprehensive Solutions for Diverse Industries

Harness the power of our end-to-end solutions, tailored to meet the unique demands of various sectors, ensuring efficiency, reliability, and excellence in every step.

Chemicals

Logistics Service Providers

Challenges with Railcars and Rail Boxes Visibility

Rail car tracking typically involves railway portals utilizing the train’s GPS or RFID, a system that brings about specific challenges.

CHALLENGE #1

Time-delayed or incorrect information about railcars, such as when the train (rake) is tracked as a unit.

CHALLENGE #2

Lack of information on railcar availability and pickup readiness through full/empty status and usage cycle status.

CHALLENGE #3

Inability to optimize rail trips creating excess railcar inventory, lack of railcars when needed, or high rental cost.

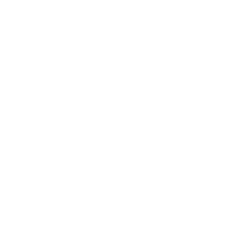

How Roambee's Solution Works for Railcars

Visibility

Better visibility by combining order information with real-time location and condition data from IoT sensors affixed on railcars capable of recharging using renewable solar power and data streams from rail operations.

Alerts & Signals

Built on verifiable visibility, alerts & signals empower better decisions and drive automation. For example, a business signal about idling railcars is derived by sensing use cycle milestones and full/empty status, enabling retrieval and utilization.

Intelligence

Use AI-powered network insights & foresights for better supply chain planning & execution. For example, score railcar utilization (cycle times) by geography, season, customer, and vendor and forecast this key performance indicator (KPI).

Experience the Power of Roambee

Experience the Power of Roambee

Alerts & Signals to Help You Make the Right Decisions

Enhance your decision-making process with real-time alerts and actionable insights, ensuring prompt reaction to any irregularities or disruptions in your railcar transportation operations.

Asset Signals

Route Plan Deviations

of Railcars and Trains

Electronic Proof of

Delivery (ePoD)

Temperature & Humidity

Excursion

Mean Kinetic

Temperature (MKT)

Time Out of

Refrigeration (TOR)

ETA & Delay Signals

Pick-up & Delivery

Location & Geofencing

In Use (On a Shipment)

Idle at Docks

or Yards

Idle at a Customer

or Vendor Location

Route Plan Deviations

of Railcars and Trains

Electronic Proof of

Delivery (ePoD)

Temperature & Humidity

Excursion

Mean Kinetic

Temperature (MKT)

Time Out of

Refrigeration (TOR)

ETA & Delay Signals

Pick-up & Delivery

Location & Geofencing

In Use (On a Shipment)

Idle at Docks

or Yards

Idle at a Customer

or Vendor Location

Business Signals

Full/Empty Status of Railcars

Transloading Confirmation

Asset Availability to Ship Product

Full/Empty Status of Railcars

Transloading Confirmation

Asset Availability to Ship Product

Delivery and Pickup Window Schedule

Order Fulfillment in Asset Operations & Product Shipping Operations

Wrong and Missed Connections of Railcars

Delivery and Pickup Window Schedule

Railcar Availability to Ship Product

Wrong and Missed Connections of Railcars

Order Fulfillment in Railcar Operations & Product Shipping Operations

Idling/Aging of Railcars at Docks, Yards, Warehouses, or Customer/Vendor Locations

Cold Chain Quality Control Compliance Prediction of Goods Inside Railcars

Order Fulfillment in Railcar Operations & Product Shipping Operations

Order Fulfillment in Asset Operations & Product Shipping Operations

Cold Chain Quality Control Compliance Prediction of Goods Inside Railcars

Revenue Recognition in Asset Operations & Product Shipping Operations

Revenue Recognition in Railcar Operations & Product Shipping Operations

Order Fulfillment in Asset Operations & Product Shipping Operations

Revenue Recognition in Asset Operations & Product Shipping Operations

Revenue Recognition in Railcar Operations & Product Shipping Operations

Idling/Aging of Railcars at Docks, Yards, Warehouses, or Customer/Vendor Locations

Business Outcomes with

Roambee

Business Outcomes with Roambee

Revolutionize your rail transport operations with Roambee. Achieve premium road transport-level predictability, maximize revenue per railcar, and seamlessly orchestrate railcar placements and retrievals. Enhance sustainability while maintaining premium service levels.

- Bring premium road transport-level predictability into your cost-effective rail operations.

- Increase "revenue per railcar" through better utilization as an asset operator or an asset user.

- Seamlessly orchestrate placing and retrieving railcar or rail boxes from any location, station, yard, or customer site.

- Increase sustainability by leveraging low-carbon impact rail mode while maintaining premium road shipment mode's service levels.

Empowering you with our Intelligence

Unlock Roambee’s AI-powered insights for railcar management. Dive into OTIF scoring, asset cycle times, and dwell and detention analytics. With Roambee’s foresights, anticipate dwell times, optimize asset routing, and ensure consistent OTIF and Quality Control (QC).

Insights

- Rail on time and in full (OTIF) scoring by lanes, carriers, and nodes.

- Asset cycle time analytics by geography, season, customer, vendor, etc.

- Dwell time and detention analytics by facility, unloading docks, customer/vendor yards, and stations.

Foresights

- Asset dwell time and cycle time predictions by customer, vendor, geography, and season.

- Asset routing and returns recommendations for optimization.

- OTIF and quality control (QC) predictions by lanes and rail operators.

Streamlining Railcar Management for a British Multinational

- About: A prominent British multinational sought to automate and enhance its railcar management operations globally.

- Roambee's Intervention: Using Roambee's heat maps, the company gained precise insights into consumption patterns and dwell times at every customer site. This intelligence facilitated optimized deliveries, timely railcar retrievals, and accurate forward/reverse ETAs.

- Results: The integration of these insights led to a more streamlined and automated railcar management process.

- Impact: The company achieved efficient railcar operations, timely deliveries, and improved asset utilization.

Resources on Visibility & Intelligence

Webinar

Part 1: Telematics Aggregation vs. Sensor Driven Supply Chain Visibility

E-book

Making Smart Supply Chain Decision in the New Normal