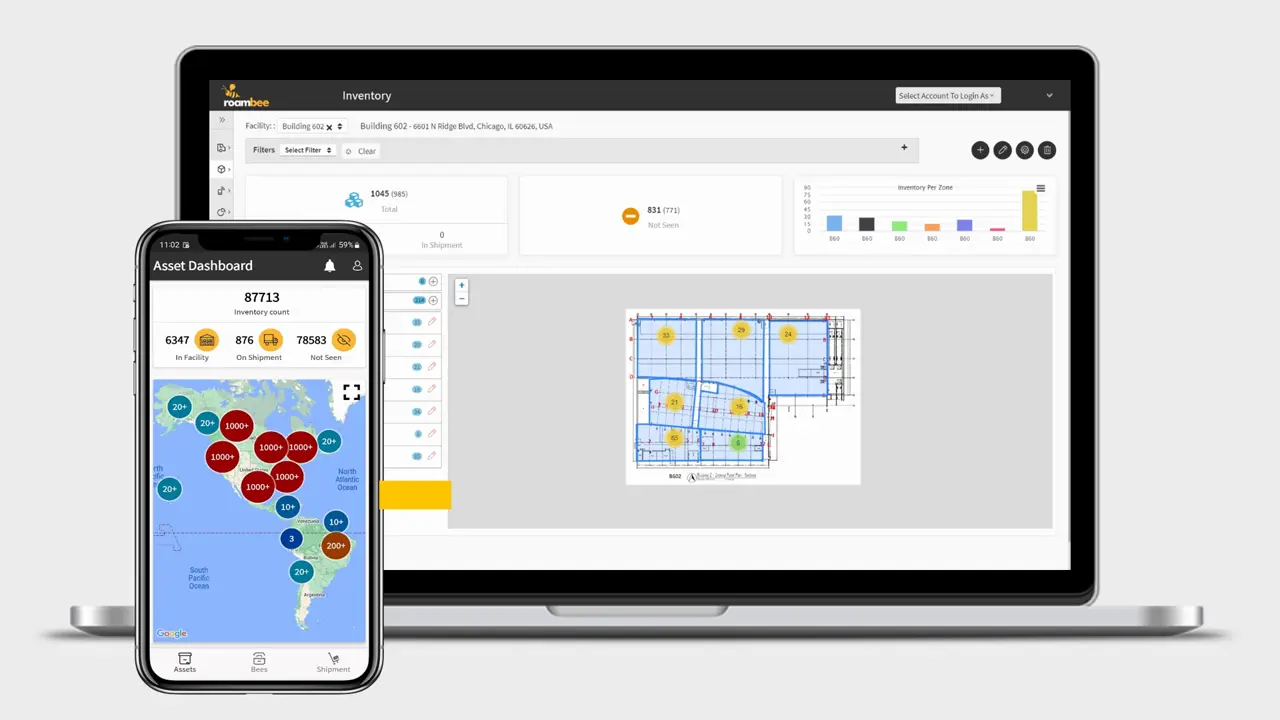

Better Visibility & Intelligence for Cold Storage Warehouses

Build auditable and definitive cold chain compliance across hundreds or thousands of remote cold chain warehouses in the world with contextual, automated, touchless, active temperature monitoring technology and contextual analytics for every stakeholder involved.

Comprehensive Solutions for Diverse Industries

Harness the power of our end-to-end solutions, tailored to meet the unique demands of various sectors, ensuring efficiency, reliability, and excellence in every step.

Food & Beverages

Logistics Service Providers

Challenges with Cold Storage Warehouse Visibility

Cold chain warehouses are often tracked using passive or active data loggers, an approach that leads to certain challenges.

CHALLENGE #1

Manual touchpoints in passive data logging that make data delayed and unusable for preventive action.

CHALLENGE #2

Visibility limited to a zone level, not a product level, even if data is captured in real-time.

CHALLENGE #3

Inability to identify and foresee an impact on quality control (QC) or stock expiry date changes at an aggregate level.

How Roambee's Solution Works for Cold Storage Warehouses

Visibility

Built on verifiable visibility, alerts & signals empower better decisions and drive automation. For example, a business signal about an optimal warehouse temperature setting is derived by sensing internal and external conditions to enable quality compliance (QC).

Alerts & Signals

Built on verifiable visibility, alerts & signals empower better decisions and drive automation. For example, a business signal about a security breach is derived by sensing unauthorized container door openings and routing, enabling you to respond promptly.

Intelligence

Use AI-powered network insights & foresights for better supply chain planning & execution. For example, score quality compliance (QC) by zone, warehouse, and region and forecast this key performance indicator (KPI).

Experience the Power of Roambee

Experience the Power of Roambee

Alerts & Signals to Help You Make the Right Decisions

Enhance your strategic decision-making with real-time alerts and actionable business insights, ensuring swift and effective responses to any variances or disruptions in your cold storage warehouse operations.

Asset Signals

Mean Kinetic

Temperature (MKT)

Time Out of

Refrigeration (TOR)

Humidity and

Humidity Excursion

Temperature and

Temperature Excursion

Mean Kinetic

Temperature (MKT)

Time Out of

Refrigeration (TOR)

Humidity and

Humidity Excursion

Temperature and

Temperature Excursion

Business Signals

Stock Expiry Date Prediction

Optimal Warehouse Temperature Setting

Cold Chain Quality Control Prediction

Stock Expiry Date Prediction

Optimal Warehouse Temperature Setting

Cold Chain Quality Control Prediction

Business Outcomes with

Roambee

Business Outcomes with Roambee

Revolutionize your cold storage management with Roambee. Automate quality controls, ensure cold chain compliance across diverse temperature zones, and mitigate costs from quality degradation. Enhance sustainability with energy-efficient HVAC profiles tailored to every season.

- Automate quality controls (QC) remotely at any facility with live temperature data and analytics.

- Achieve cold chain compliance across every zone in the warehouse, catering to different products and temperature ranges such as frozen, refrigerated, and ambient.

- Mitigate costs arising from quality degradation, contamination, or security compromises leading to discarded goods.

- Minimize carbon footprint by saving power consumption with optimal heating, ventilation, and air-conditioning (HVAC) profiles for every season.

Empowering you with our Intelligence

Unlock the power of AI-powered insights for cold storage management. Dive deep into cold chain compliance, humidity analytics, and weather-based correlations. With Roambee’s foresights, anticipate warm zones, receive timely humidity warnings, and get predictive temperature recommendations.

Insights

- Cold chain compliance by zone, warehouse, and region.

- Humidity analytics and compliance by zone, warehouse, and region.

- Weather-based warehouse condition correlation.

Foresights

- Warm zone predictions by season and temperature settings.

- Humidity warnings by season and temperature settings.

- Predictive temperature recommendations based on weather.

Enhancing Cold Chain Compliance for a Global Food Conglomerate

- About: A leading global food company aimed to fortify its vendor-managed warehouses against temperature fluctuations in warmer regions.

- Roambee's Intervention: Leveraging Roambee's insights, the company pinpointed the top 50 zones out of 487 across 265 warehouses that were responsible for over 75% of their cold chain compliance breaches.

- Results: With targeted interventions, the company achieved a 10X reduction in aggregate temperature excursions, ensuring optimal product quality and longevity.

- Impact: The company ensured consistent product quality, extended shelf life, and enhanced cold chain compliance across its warehouses.

Resources on Visibility & Intelligence

Webinar

How IFCO Has Found The Missing Piece Critical To Your Supply Chain

Guide

Making Smart Supply Decisions in the New Normal