100x Better

Supply Chain Predictions.

Better Visibility + Intelligence

of Shipments & Assets.

100x Better

Supply Chain Predictions.

Better Visibility + Intelligence

of Shipments & Assets.

Dive into a world where AI meets item-level, real-time sensor data and curated feeds, turning your supply chain visions into clear, accurate KPI forecasts, and sustainability metrics. With Roambee, every move is a step ahead, making your decisions sharper, simpler, and smarter.

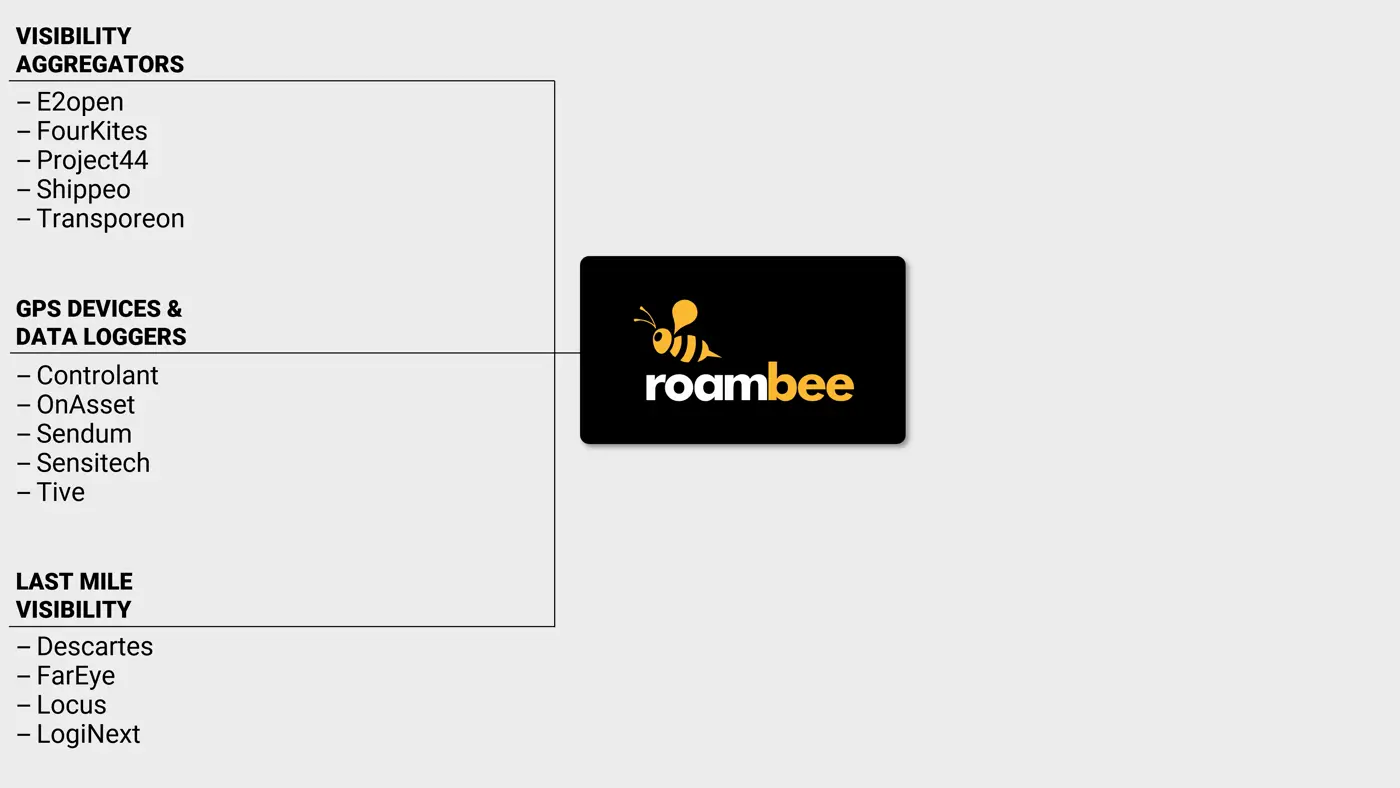

Roambee: Unifying Visibility Data for Automated Supply Chain Execution

Roambee: Unifying Visibility Data for Automated Supply Chain Execution

Our platform offers intelligent business signals by consolidating carrier milestones, sensor data, last-mile visibility, order information, Scope 3 emissions, and potential supply chain risk triggers. Coupled with our assisted analytics program and a 24×7 control tower service, Roambee is a fully managed visibility and intelligence solution, enabling supply chain automation.

Trusted by 300+ Industry-

Leading Brands

Trusted by 300+ Industry Leading Brands

Join the ranks of top-tier enterprises who have transformed their supply chain operations with Roambee. Our solutions are the trusted choice for achieving unrivaled visibility and intelligent forecasting.

4 of the Global Top 10

Enterprises in Pharma &

Lifesciences Run on Roambee

6 of the Global Top 10

Enterprises in Food &

Beverages Run on Roambee

4 of the Global Top 10

Enterprises in

Electronics Run on Roambee

6 of the Top Global 10

Enterprises in

Chemicals Run on Roambee

3 of the Global Top 10

Enterprises in

Automotive Run on Roambee

4 of the Global Top 10

Enterprises in

Logistics Run on Roambee

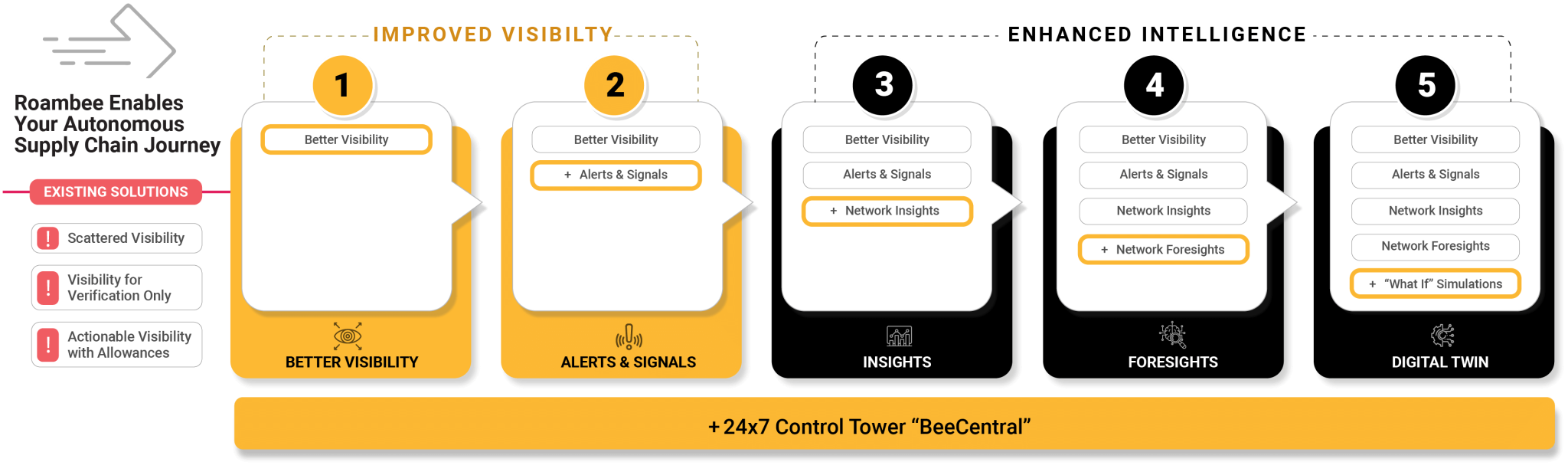

Accelerating Supply Chain Autonomy

Enabling Your Autonomous Supply Chain Journey in 5 Simple Steps

Experience the Power of Roambee

Fully Managed Visibility & Intelligence Solutions

Roambee provides a comprehensive solution to enhance supply chain transparency, automation, and sustainability. Our services are fully managed to include better visibility, analytics, and a 24×7 control tower, all tailored to meet the specific needs of your industry.

Hear It From Our Satisfied Customers

Roambee recognized as a leader in Asset Tracking

Logistics Quality

Supervisor at Ferrero

Ferrero is known for its quality and excellence. To maintain its brand promise, we work to proactively mitigate and address all non-compliant events in our cold chain, from warehouses to distributors, using sensor-driven cold chain visibility and intelligence. Roambee provides business signals such as Quality Controls (QC) prediction signals, Estimated Time of Arrival (ETA) signals, On-Time, In-Full (OTIF) signals, and more, for better forecast accuracy.

Dy. General Manager – Warehouse, Logistics, and EXIM for Environmental Catalysts at BASF

"At BASF, ensuring transportation transparency, customer delight, and building climate neutrality into our supply chain is a priority. It means working toward On-Time, In-Full (OTIF) deliveries of our containers from origin to ports of import and further to our plant locations inland, including handling of temperature and humidity conditions within the container for safe and environment-friendly transport. Roambee delivers supply chain intelligence that can help us mitigate risks caused by delays, security breaches, and factors impacting sustainability goals."

Manager - Commercial Quality at Mondelēz International

"Mondelēz International is guided by its values of authenticity, integrity, and transparency. It’s imperative for us to operate a cold chain that caters to high standards of quality and customer service. Roambee’s platform delivers real-time supply chain intelligence that helps to significantly reduce quality compromise in our cold chain by proactively attending to temperature excursion signals and delivery schedule changes for On-Time, In-Full (OTIF), in-condition, and sustainable fulfilment."

Better Supply

Chain Visibility

Delve into Roambee’s Visibility Platform, your gateway to comprehensive logistics and operational asset management. Embrace a realm where monitoring shipments and operational assets becomes seamless, and adaptability meets your unique business needs.

Better Supply

Chain Intelligence

Navigate the complexities of global logistics with Roambee’s Intelligence Platform. Uncover a world where real-time monitoring, geospatial insights, and anticipatory decisions empower your supply chain management. Delve deeper to unlock proactive solutions.

Recognized by the Industry as a Leader

CSCMP

Inc.

Inc.’s "Best in Business 2023" in AI & Data

AI Breakthrough

Roambee recognized with an award for "Best AI-based Solution for Supply Chain."

G2.com

"Leader - Spring 2023" on the real-time G2 Grid for the top Asset Tracking Software Products

CSCMP Edge

One of Top 6 Finalists for the Supply Chain Innovation Award

CB Insights

'Outperformer' in Pharma Supply Chain Visibility ESP Vendor Matrix - July 2022

CRN

The 10 Hottest IoT Startups of 2021 (so far)

SDCE

Top Supply Chain Project Award

CSCMP

Winner of the 2023 Supply Chain Innovation Award at EDGE 2023

Inc.

Inc.’s "Best in Business 2023" in AI & Data

AI Breakthrough

Roambee recognized with an award for "Best AI-based Solution for Supply Chain."

SDCE

Roambee's CEO Sanjay Sharma named a winner of "Pros to Know"

G2.com

"Leader - Spring 2023" on the real-time G2 Grid for the top Asset Tracking Software Products

CSCMP Edge

One of Top 6 Finalists for the Supply Chain Innovation Award

CB Insights

'Outperformer' in Pharma Supply Chain Visibility ESP Vendor Matrix - July 2022

FDA

A Winnder of FDA's Tech-Enabled Food Traceability Challenge

SDCE

Top Supply Chain Project Award

supply chain technology with industry leaders.

Supply Chain Tech Podcast

with Roambee

supply chain technology with industry leaders.

Supply Chain Tech Podcast with Roambee

Blogs & Resources

Webinar

Part 1: Telematics Aggregation vs. Sensor Driven Supply Chain Visibility

Webinar

How to make smart supply chain decisions in the new normal

Case Study

This Manufacturer is Boosting Its Ice Cream Supply Chain Quality Compliance with Roambee